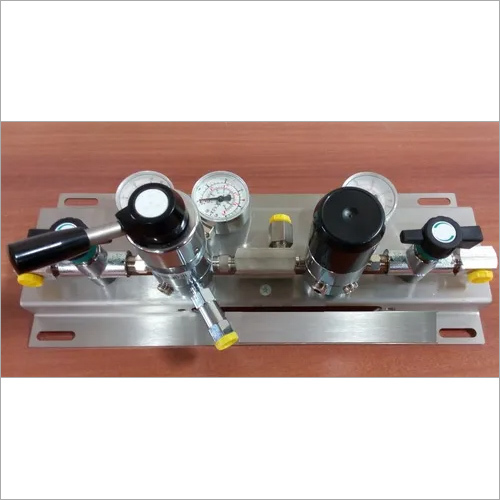

Gas Distribution System

1799.0 INR/Unit

Product Details:

- Model No GDS-1500

- Material Stainless Steel (SS304/SS316)

- Machine Type Gas supply and control apparatus

- Processing Type Automatic/Manual

- Application Laboratories, medical facilities, industrial plants, and research centers.

- Function Centralized and controlled distribution of various gases from a source to multiple outlets.

- Usage Safely regulate and deliver process gases including oxygen, nitrogen, hydrogen, argon and other specialty gases.

- Click to view more

X

Gas Distribution System Price And Quantity

- 1 Unit

- 1799.0 INR/Unit

- 6 lines (customizable)

- 0-16 bar adjustable

- Gas Distribution System

- Digital flow and pressure indicators

- Stainless steel pressure and flow gauges

- Standard tube connectors (SS)

- 0-250 bar

- Integrated alarm system

- Solenoid valve interfaced with PLC control

- Polished and anti-corrosive

- Frame mounted, floor standing

Gas Distribution System Product Specifications

- Safely regulate and deliver process gases including oxygen, nitrogen, hydrogen, argon and other specialty gases.

- Gas supply and control apparatus

- Laboratories, medical facilities, industrial plants, and research centers.

- Stainless Steel (SS304/SS316)

- 1500mm x 600mm x 1800mm Millimeter (mm)

- GDS-1500

- Approx. 120 kg Kilograms (kg)

- Automatic/Manual

- Centralized and controlled distribution of various gases from a source to multiple outlets.

- 6 lines (customizable)

- 0-16 bar adjustable

- Gas Distribution System

- Digital flow and pressure indicators

- Stainless steel pressure and flow gauges

- Standard tube connectors (SS)

- 0-250 bar

- Integrated alarm system

- Solenoid valve interfaced with PLC control

- Polished and anti-corrosive

- Frame mounted, floor standing

Gas Distribution System Trade Information

- 10 Unit Per Day

- 1 Week

- All India

Product Description

Chemix Speciality Gases and Equipments, a 2006 established company manufactures Gas Distribution System, a cost effective method of gas system control that cuts down on the time needed to replace cylinders. Gas can be transported from one location to another through a piping system attached with a few apertures for multiple connections. This wall mounted gas distribution system is leakage proof and can be trusted for accuracy.

Gas Distribution System Specifications:

- Distribution Type : Pipe System

- Pipe Material : Metal

- Finish : Coated

- Surface treatment : Perfect Galvanized

Advanced Control and Safety

Equipped with a PLC-controlled solenoid valve system, the GDS-1500 ensures precise management of gas flow and pressure. Its integrated alarm system detects leaks instantly, promoting enhanced safety for critical environments such as laboratories and medical facilities. The polished, anti-corrosive stainless steel finish further extends product longevity in demanding settings.

Flexible and Customizable Gas Lines

This system is designed for versatilityfeaturing six gas lines that can be customized to your process requirements. Standard tube connectors and adjustable pressures enable seamless integration into existing infrastructures and support various applications, ranging from industrial plants to research centers.

Effortless Monitoring and Maintenance

Digital displays provide accurate, real-time data on both flow and pressure, while stainless steel gauges assure lasting durability. Frame-mounted and floor-standing, the GDS-1500 offers straightforward installation and accessibility, making maintenance and operation convenient for technical staff.

FAQs of Gas Distribution System:

Q: How does the GDS-1500 Gas Distribution System ensure safe gas delivery?

A: The GDS-1500 uses stainless steel construction, precision gauges, and an integrated alarm system for leak detection, all managed via a PLC-controlled solenoid valve. This combination secures safe and reliable operation in high-demand environments.Q: What types of gases can be distributed using this system?

A: This system is compatible with a wide range of process gases such as oxygen, nitrogen, hydrogen, argon, and other specialty gases commonly used in laboratories, medical, industrial, and research applications.Q: When would I use the digital flow and pressure indicators?

A: Digital indicators should be monitored during system operation to ensure accurate flow rates and pressures are maintained for each line, facilitating precise control and early detection of anomalies or deviations.Q: Where can the GDS-1500 be installed?

A: The frame-mounted, floor-standing design allows straightforward installation in laboratories, medical facilities, industrial plants, and research centers. Its polished, corrosion-resistant stainless steel build suits demanding environments.Q: What is the process for customizing the number of gas lines?

A: The system is designed with six lines as standard, but these can be customized based on specific process requirements during the order phase, ensuring tailored solutions for diverse applications.Q: How is maintenance performed on this gas distribution system?

A: Maintenance involves periodic inspection of the stainless steel gauges, checking connections for integrity, and verifying the functionality of the PLC and leak alarm system. The accessible design aids routine servicing and swift troubleshooting.Q: What are the main benefits of using the GDS-1500 for centralized gas distribution?

A: Users benefit from accurate digital monitoring, robust safety features, flexible customization, and ease of integration. Its automatic/manual control options and anti-corrosive construction make it exceptionally reliable for centralized gas management.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free